The BrightLoop process has become a focal point in the discussion around clean energy technologies. With its promise to revolutionize hydrogen production while maintaining a net-negative carbon footprint, it’s no wonder that many are curious: Is BrightLoop in production yet?

Understanding the BrightLoop Process

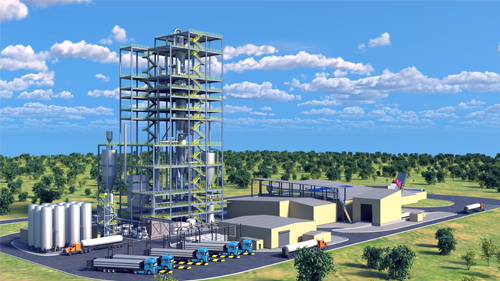

BrightLoop is an innovative chemical looping technology developed by Babcock & Wilcox (B&W). This groundbreaking method uses a circulating medium to separate carbon from other elements during combustion. The primary goal is to facilitate efficient hydrogen generation while significantly reducing greenhouse gas emissions. Unlike traditional methods, the BrightLoop process focuses on a sustainable and scalable approach to large-scale hydrogen production.

How Does BrightLoop Work?

At the heart of the BrightLoop process lies its proprietary material—a solid medium capable of transferring oxygen between reactions. This medium plays a pivotal role in converting hydrocarbons into high-purity carbon and hydrogen streams. The result? A cleaner process that aligns with global sustainability goals.

By implementing B&W’s BrightLoop technology, industries can reduce their dependence on fossil fuels while maintaining operational efficiency. The system is designed to work with a variety of feedstocks, including natural gas, coal, and biomass.

The Current Status: Is BrightLoop in Production Yet?

As of now, BrightLoop technology is in its developmental and pilot phases. While it has not reached full-scale commercial production, significant advancements are being made. Babcock & Wilcox continues to refine the process, focusing on scaling its operations to meet the demands of industrial applications.

Pilot Projects and Future Prospects

B&W has already launched multiple pilot projects to test the feasibility of the BrightLoop process in real-world conditions. These projects aim to assess the system’s efficiency, scalability, and economic viability. Early results have been promising, indicating that BrightLoop could soon transition from pilot phases to full-scale production.

Key Advantages of the BrightLoop Process

1. Net-Negative Carbon Emissions

BrightLoop’s ability to capture and utilize carbon during the process is a game-changer. By achieving net-negative emissions, this technology positions itself as a leader in the fight against climate change.

2. Versatile Feedstock Options

Unlike many existing hydrogen production technologies, BrightLoop is compatible with diverse feedstocks. This flexibility makes it an attractive solution for industries looking to reduce their carbon footprint.

3. Scalable for Industrial Use

The modular design of BrightLoop ensures that it can be adapted for various industrial applications, making it a viable option for large-scale production.

4. Efficient Hydrogen Production

The process enables the production of high-purity hydrogen, which is critical for industries such as transportation, energy storage, and chemical manufacturing.

Challenges in Scaling BrightLoop Technology

Despite its immense potential, BrightLoop faces challenges typical of any emerging technology. Scaling from pilot projects to commercial production requires significant investment, rigorous testing, and regulatory approvals. Furthermore, integrating the technology into existing industrial setups may require substantial modifications.

BrightLoop and the Global Energy Landscape

The implementation of B&W’s BrightLoop technology aligns with the global shift toward cleaner energy. Hydrogen, often referred to as the fuel of the future, plays a crucial role in decarbonizing heavy industries and transportation sectors. By prioritizing hydrogen generation through sustainable methods, BrightLoop could help accelerate the transition to a greener economy.

What’s Next for BrightLoop?

The next phase for BrightLoop involves scaling up its pilot programs and exploring partnerships with industries that can benefit from its technology. With global attention focused on achieving net-zero carbon goals, the demand for innovative solutions like BrightLoop is higher than ever.

Conclusion

So, is BrightLoop in production yet? While it hasn’t reached full-scale commercialization, the groundwork is being laid for its future success. With its unique approach to hydrogen production and carbon capture, BrightLoop has the potential to transform the energy landscape. As industries and governments work together to combat climate change, technologies like BrightLoop will undoubtedly play a central role in achieving these ambitious goals.